High speed bridge gantry machining center

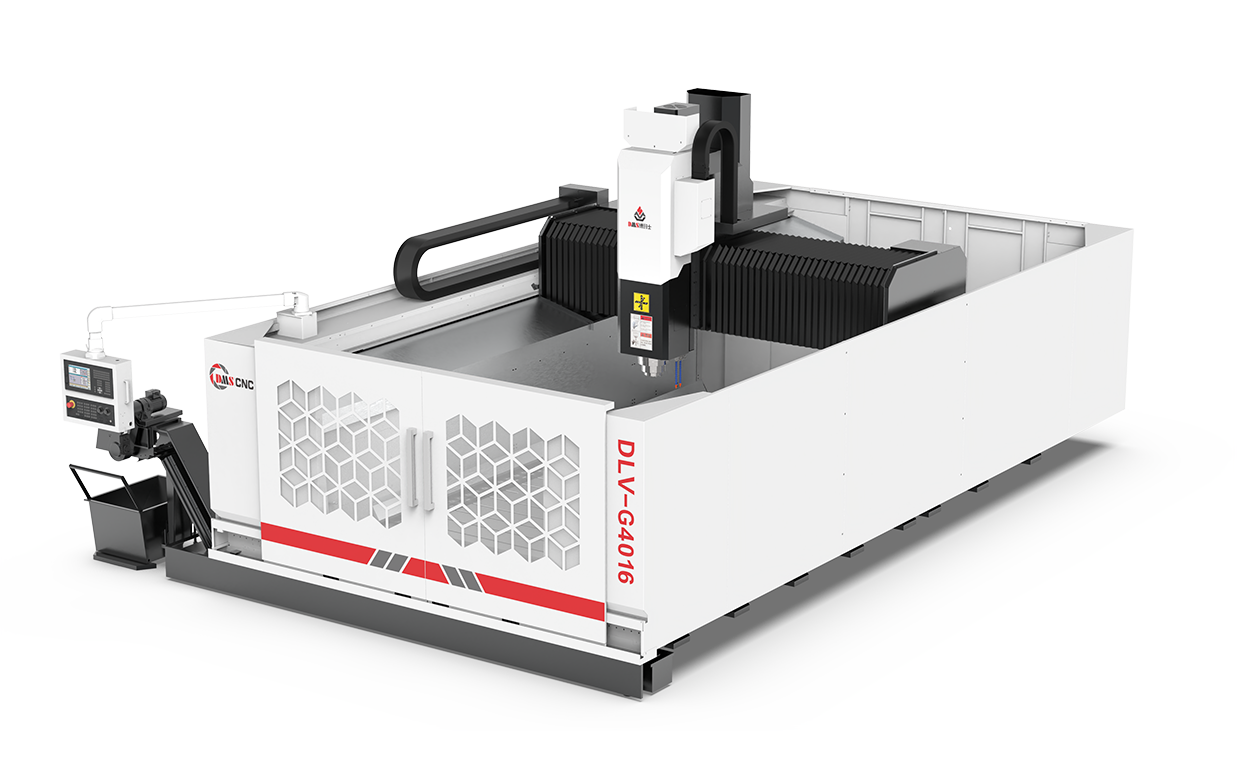

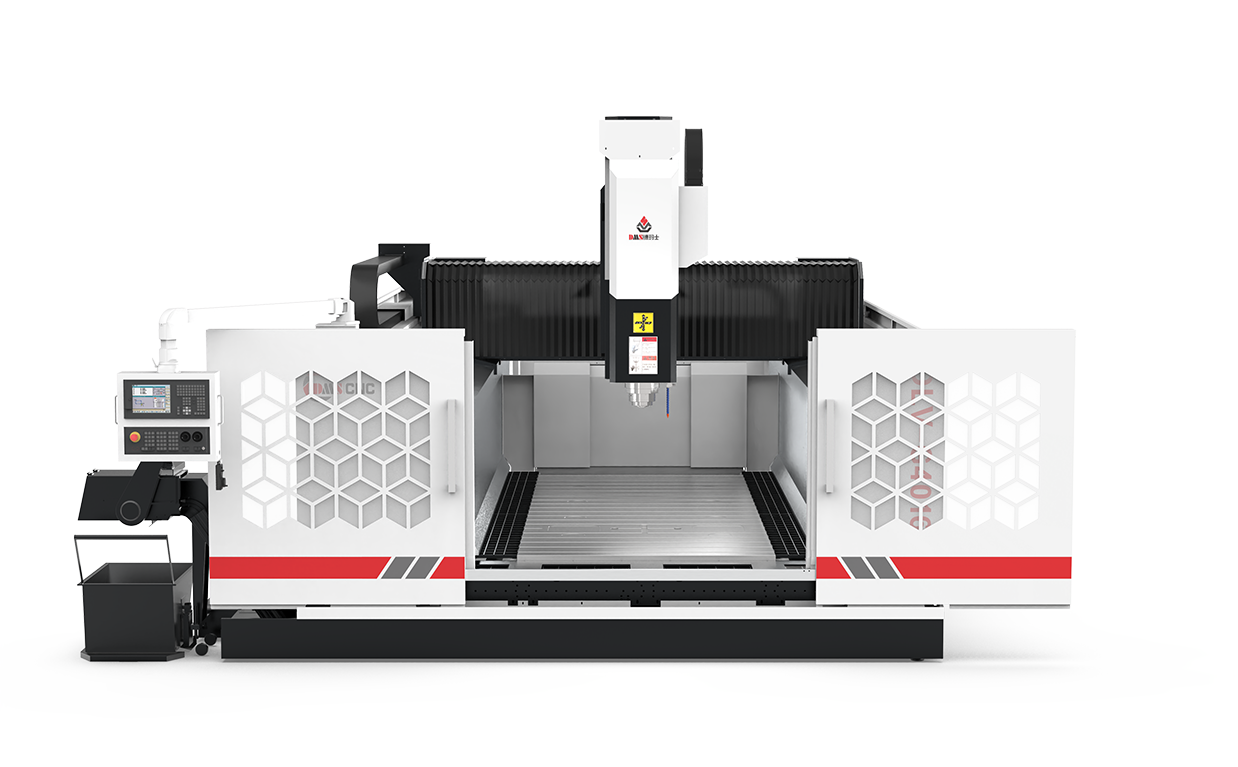

DLV-G4016(6016)

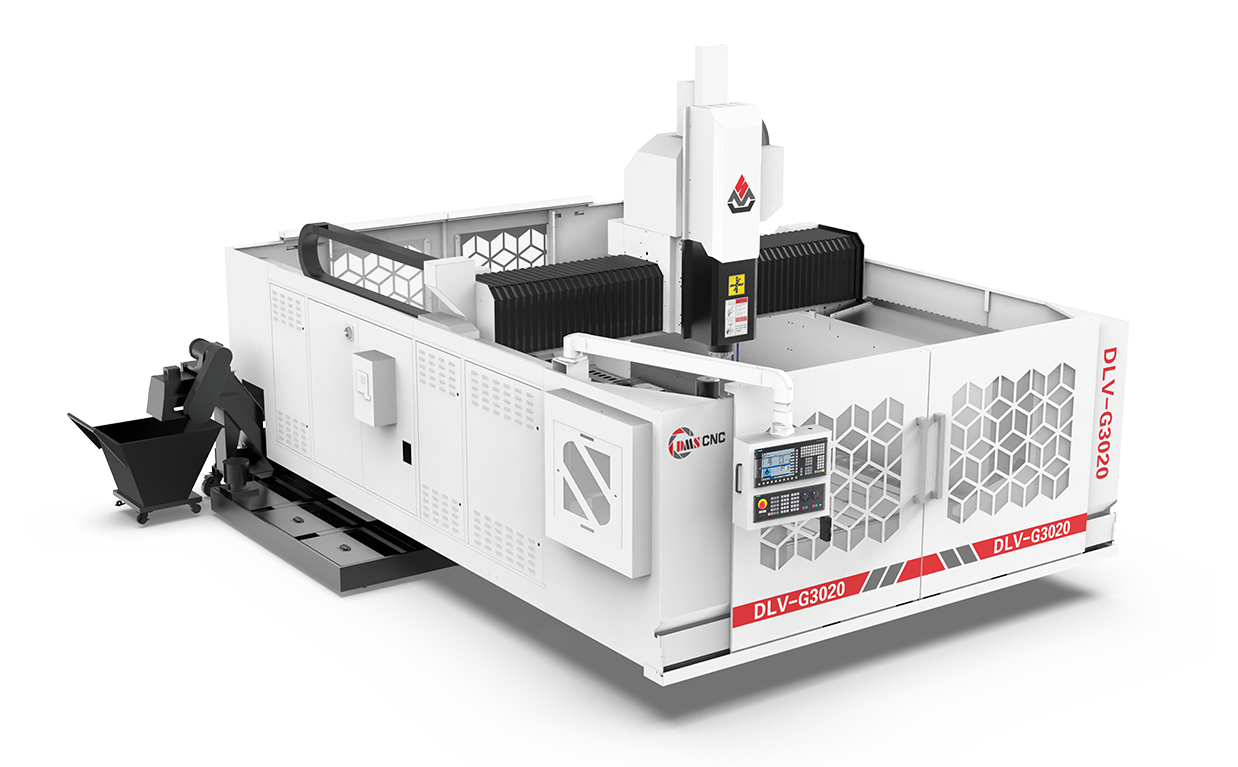

This product is developed and manufactured according to market demand and is widely used in aerospace, new energy vehicles, mechanical equipment, rail transportation, industrial profile processing, and drilling, tapping, milling, boring and other materials for orderly precision processing of aluminum alloys, steel, iron, copper parts and PVC. The main control parts, power parts and drive parts of the machine are all selected from world-renowned brands. The whole machine bed, moving column structure and spindle head are made of high-quality mineral cast iron. The new reasonable structure has high strength and rigidity. The casting table can be equipped with professional pneumatic clamps and four-axis clamps, which ensures the stable operation, high processing accuracy, high efficiency and durability of the machine.